Barrick Gold says Reko Diq making strides with nearly 1,000 workers on-site

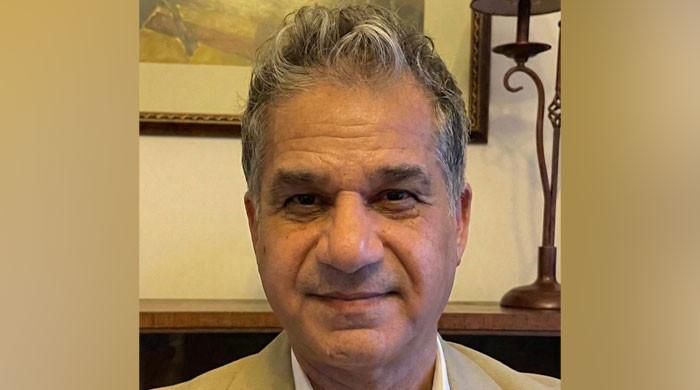

At Reko Diq Suppliers Roadshow, Geo News spoke with Martin Henuse, a senior exec at the miner, to discuss project’s progress

May 29, 2025

Barrick Gold is making swift progress at the Reko Diq copper-gold project, with a large number of workers on-site and infrastructural developments underway, a senior executive told Geo News in an exclusive interview.

At the Reko Diq Suppliers Roadshow, Geo News spoke with Martin Henuse, a senior executive at the mining giant, to discuss the project’s progress, local impact, and long-term vision. Below is their conversation:

Question: How is the progress so far?

Henuse: It’s moving incredibly fast. Right now, we have nearly 1,000 employees on-site at Reko Diq. We’ve moved massive amounts of earth, built accommodations, secured a water supply, and started road construction. Everything is on track.

Question: Barrick has a legacy of community investment. What’s being done here?

Henuse: Our strategy has always been to invest in local communities. Here, we’ve already built schools and hospitals. The growth you’ll see as we scale up will be exponential. The proof? Visit Reko Diq—you’ll see the impact firsthand.

Question: Critics claimed this project would exclude locals. How are you ensuring Pakistani participation?

Henuse: Our supply chain strategy prioritises local engagement. Every international contractor we work with must establish operations in Pakistan, hire and train locals, and partner with domestic businesses. This isn’t just talk—it’s in our contracts.

Question: The first phase is a $6 billion investment. What’s the status?

Henuse: We’ve already purchased major equipment, secured approvals, and are finalising financing. By year-end, we’ll be at full speed.

Question: What about local suppliers and employment?

Henuse: We’ve hired every available worker from the community. When we asked the village elder for more trainees, he said, “You’ve already taken all our people!” That’s success. Local contractors are already on-site, and we’re expanding.

Question: The equipment and technology being used—how advanced is it?

Henuse: This isn’t just a gold mine; it’s enormous compared to typical operations. We’re bringing in 360-ton trucks, cutting-edge tech, and setting up training facilities to upskill workers, from driving light vehicles to operating massive machinery.

Question: Will training extend to suppliers or just Barrick staff?

Henuse: Suppliers must also transfer skills. Initially, they’ll bring foreign experts, but we mandate localisation. Globally, our mines are 95–100% locally staffed. Pakistan will be no different.

Question: How confident are you in achieving the first production target of 2028?

Henuse: This isn’t our first rodeo. We have top-tier subcontractors, international expertise, and a proven team. Execution is key, and we’re on track.

Question: What’s the expected output in Phase 1 vs. Phase 2?

Henuse: Phase 1: 260,000 tons of copper annually (40 truckloads/day).

Phase 2: 400,000 tons (60 trucks/day). All are transported via upgraded rail to Port Qasim.

Question: Will raw materials be processed locally?

Henuse: Not initially. A smelter needs three Reko Diq-scale projects to be viable. We’ll export raw concentrate for refining.

Question: Despite negative press, how do you view Pakistan’s potential?

Henuse: This is my 40th trip here. I’ve faced zero issues—only good people and progress. We’re committed to building confidence. Barrick believes in Pakistan, and this project will prove it.

With billions in revenue, thousands of jobs, and transformative infrastructure, Reko Diq is set to redefine Pakistan’s economic future—and Barrick is all-in to make it happen.