In plastic-breaking development, LCC enzyme may prove Pac-Man for stubborn global waste

Professor Alain Marty and team refined an enzyme capable of breaking down PET polymer into monomers

November 28, 2023

In 2010, researcher Sintawee Sulaiman embarked on a groundbreaking journey at the University of Osaka, modifying an enzyme, LCC (leaf-branch compost cutinase), initially discovered in a pile of decaying leaves.

This new enzyme was dubbed by some as plastic-eating Pac-Man a maze action video game developed and released by Namco for arcades in which an eponymous character must eat all the dots inside an enclosed maze while avoiding four coloured ghosts.

The hope was that LCC, known for breaking down the waxy coating of leaves, could also play a role in degrading plastic. Sulaiman's experiment involved exposing plastic shards to LCC, resulting in a surprising transformation overnight. The plastic, identified as PET (polyethylene terephthalate), displayed a noticeable breakdown.

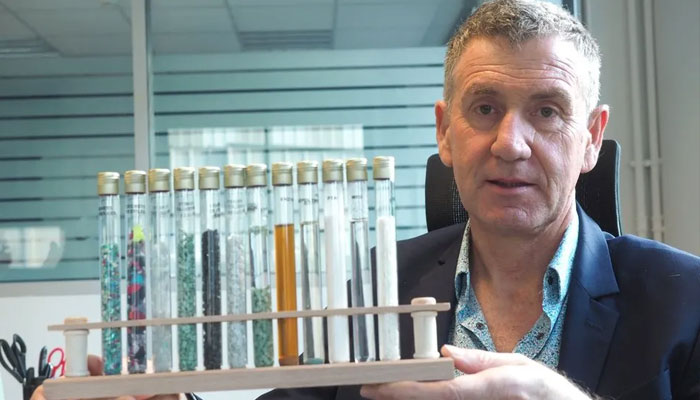

Over eight years, Professor Alain Marty and his team at the University of Toulouse refined LCC into LCCICCG, a PET-specialised enzyme capable of fully breaking down the PET polymer into its monomers.

This innovation, likened to molecular scissors separating pearls, paved the way for the establishment of Carbios, where Marty is now the chief scientific officer.

Carbios operates a demonstration plant in Clermont-Ferrand, France, resembling a microbrewery with a reactor processing PET plastic, including polyester-rich textiles.

The facility's significant machine handles polyester-rich clothing, a major contributor to global clothing fibre production. Instead of ending up in landfills or incinerators, these textiles are processed, creating soft pellets that can be repurposed.

Carbios plans to scale up its operations with a new factory in northeast France, targeting the recycling of 50,000 tonnes of PET waste annually by 2025, and collaborating with major brands like Nestle, L'Oréal, and PepsiCo.

While Carbios aims to license its process rather than become a recycler, challenges lie ahead, notably the cost. The chemical monomers produced by Carbios, though similar to those derived from petrochemicals, are expected to be around 60% more expensive.

Emmanuel Ladent, Carbios CEO, remains optimistic, anticipating reduced raw material costs as Carbios gains access to more feedstocks. The company's focus extends beyond PET, exploring ways to tackle plastics with more complex structures, like nylon.